Aluminium Casting at the Highest Level

In two of Europe’s most modern and flexible foundries, we produce extrusion billets, rolling slabs, sows and desox aluminium. With production sites in Austria and Romania, we are able to respond quickly and flexibly to the individual requirements of our customers. Our strengths lie in our complete alloy portfolio, close cooperation with customers, and the rapid implementation of customised and special products.

Sustainability and efficient recycling play a central role, just as reliable delivery throughout the entire product life cycle.

Wrought Alloys

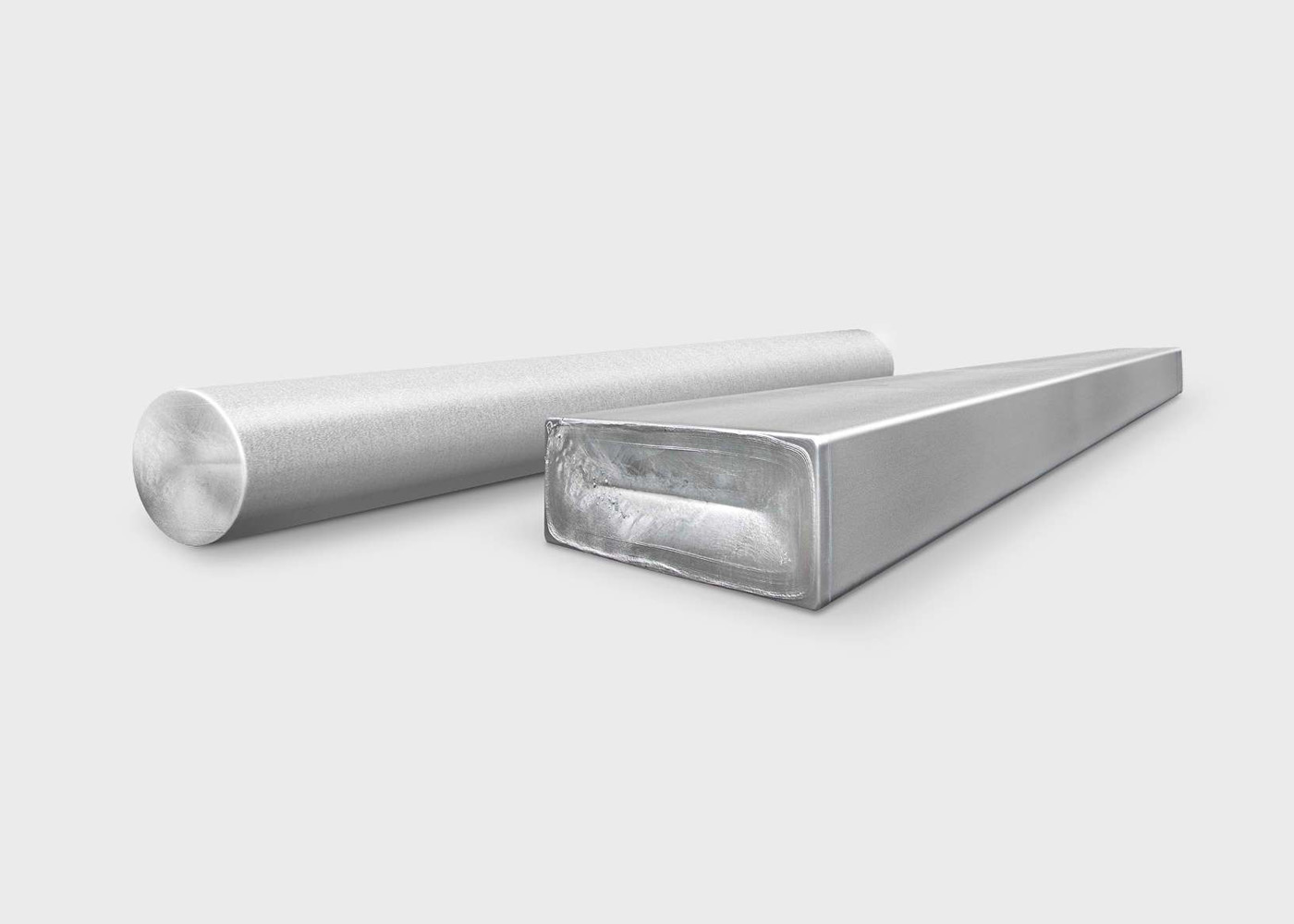

Extrusion Billets

Standard sizes:

Ø 178 mm (7″) +0 / −2

Ø 203 mm (8″) +0 / −2

Ø 229 mm (9″) +0 / −2

Ø 254 mm (10″) +0 / −2

Ø 279 mm (11″) +0 / −3

Ø 305 mm (12″) +0 / −3

Ø 330 mm (13″) +0 / −3

Ø 346 mm (13,7″) +1 / −3

Ø 381 mm (15″) +1 / −3

Lengths supplied: 500-7,200 mm

Additional dimensions available upon request.

Rolling Slabs

LHC Casting Mould – Thickness 400 mm

Standard widths available:

1,150, 1,260 and 1,400 mm

Additional widths available with minimal effort:

1,180, 1,200, 1,220, 1,240, 1,280, 1,300, 1,320, 1,340, 1,360 and 1,380 mm

LHC Casting Mould – Thickness 500 mm

Standard widths available:

1,530, 1,550 and 1,570 mm

Additional widths available with minimal effort:

1,370, 1,390, 1,410, 1,430, 1,450, 1,470, 1,490 and 1,510 mm

Additional LHC Casting Moulds:

Thickness 545 mm, width 1,550 mm

Thickness 480 mm, width 1,570 mm

Casting alloys

Sows

Weight: 750 to 950 kg

Wagstaff AirSlip®

Maximum extrusion speeds and surface quality for high‑end applications

With the innovative Wagstaff AirSlip® technology, we are setting new benchmarks in aluminium extrusion. Consistently applied processes ensure outstanding surface quality and optimum extrudability – even for demanding requirements in the high‑end segment.

Thanks to Wagstaff AirSlip®, casting with extremely thin edge zones of less than 0.3 mm (300 µm) is possible. This enables maximum precision and efficiency while simultaneously achieving significantly increased extrusion speeds.

Discover the benefits of Wagstaff AirSlip® technology for your most demanding projects!

Find out more about our

sustainable aluminium products

Are you ready for

HAI-end casting products?

Hermann Fellner

Divisional Manager, Casting Metal Management & Sales