Here we mean in particular high-quality aluminium profiles.

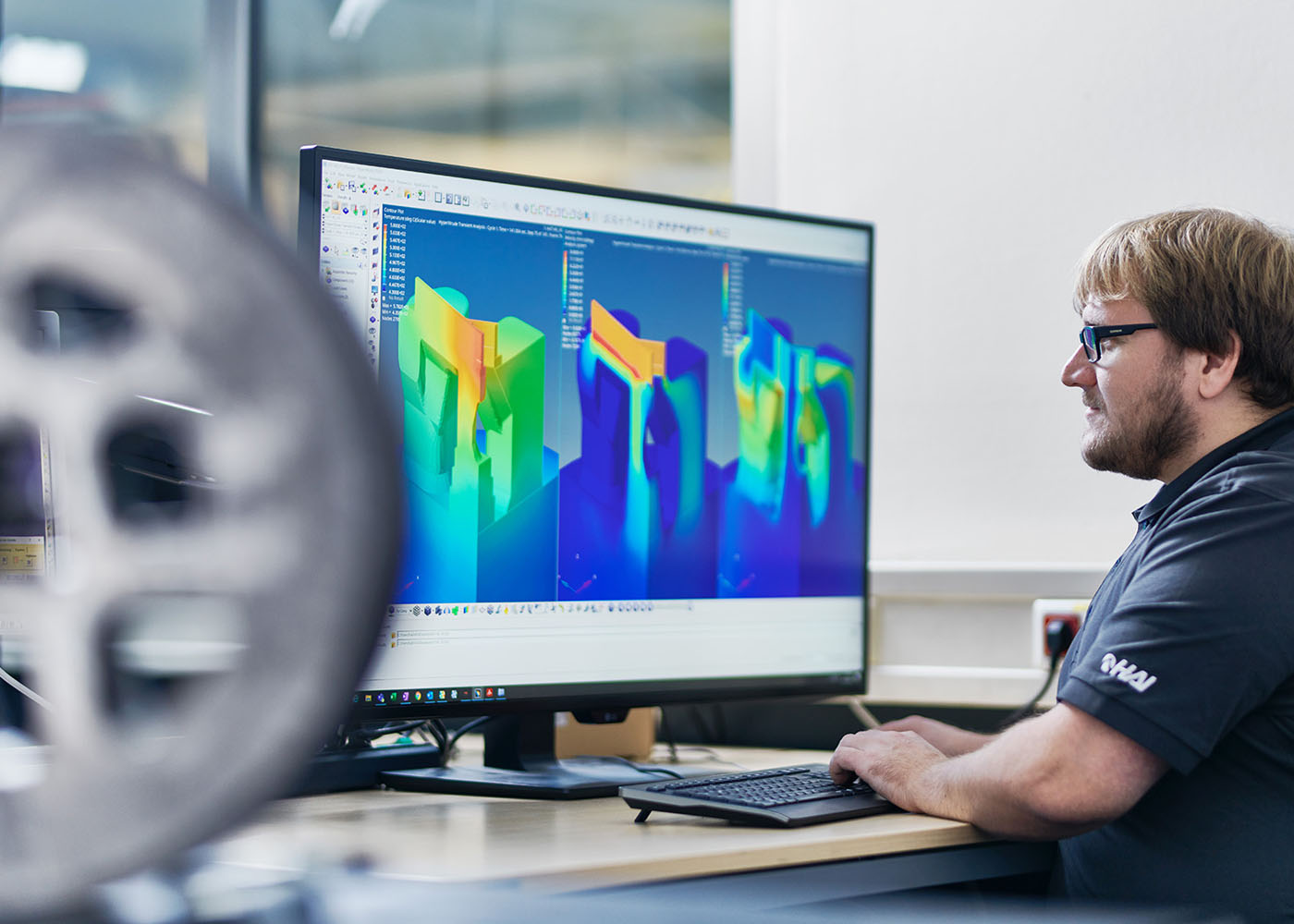

Our own toolmaking operation gives us an edge

HAI has its own toolmaking operations at its extrusion sites. This enables us to satisfy our respective customers’ requirements even more quickly and flexibly, and to implement innovations even more responsively by working as a team together with our customers. So sometimes we anticipate the production needs. This increases our speed of implementation, it makes us less dependent on others, and it means that we can get innovations for our customers onto the machine even more quickly.

ASI Performance Standard certification

HAI has received the Aluminium Stewardship Initiative (ASI) Performance Standard certification for the Extrusion business area at its Ranshofen, Soest and Cris sites. As part of an independent audit conducted by TÜV Rheinland Cert GmbH, the three extrusion plants were assessed against 59 criteria covering the areas of corporate governance, environmental responsibility and social responsibility.

As an innovation leader providing integrated aluminium solutions, sustainable corporate governance is a core element of HAI’s corporate strategy. The certification marks an important milestone: in addition to the two foundries, all three extrusion plants of the HAI Group are now certified to the highest industry standards.

With its sustainable aluminium end-to-end solutions, HAI actively supports its customers in reducing their CO₂ footprint, particularly in the transport, industrial and construction sectors.

“The HAI Group deliberately invests resources and capital in the sustainable design of our business processes along the entire value chain. This includes complex yet highly meaningful certifications such as the ASI Performance Standard. Our two foundries and three extrusion plants demonstrably operate in accordance with the highest industry standards, enabling us to produce sustainable aluminium products for a better future.”

Markus Schober, COO HAI Group