zero emissions.

Aluminium solutions

for e-mobility

- Battery housings

- Battery enclosures and trays

- Battery crash-protection units

Uncompromising innovation

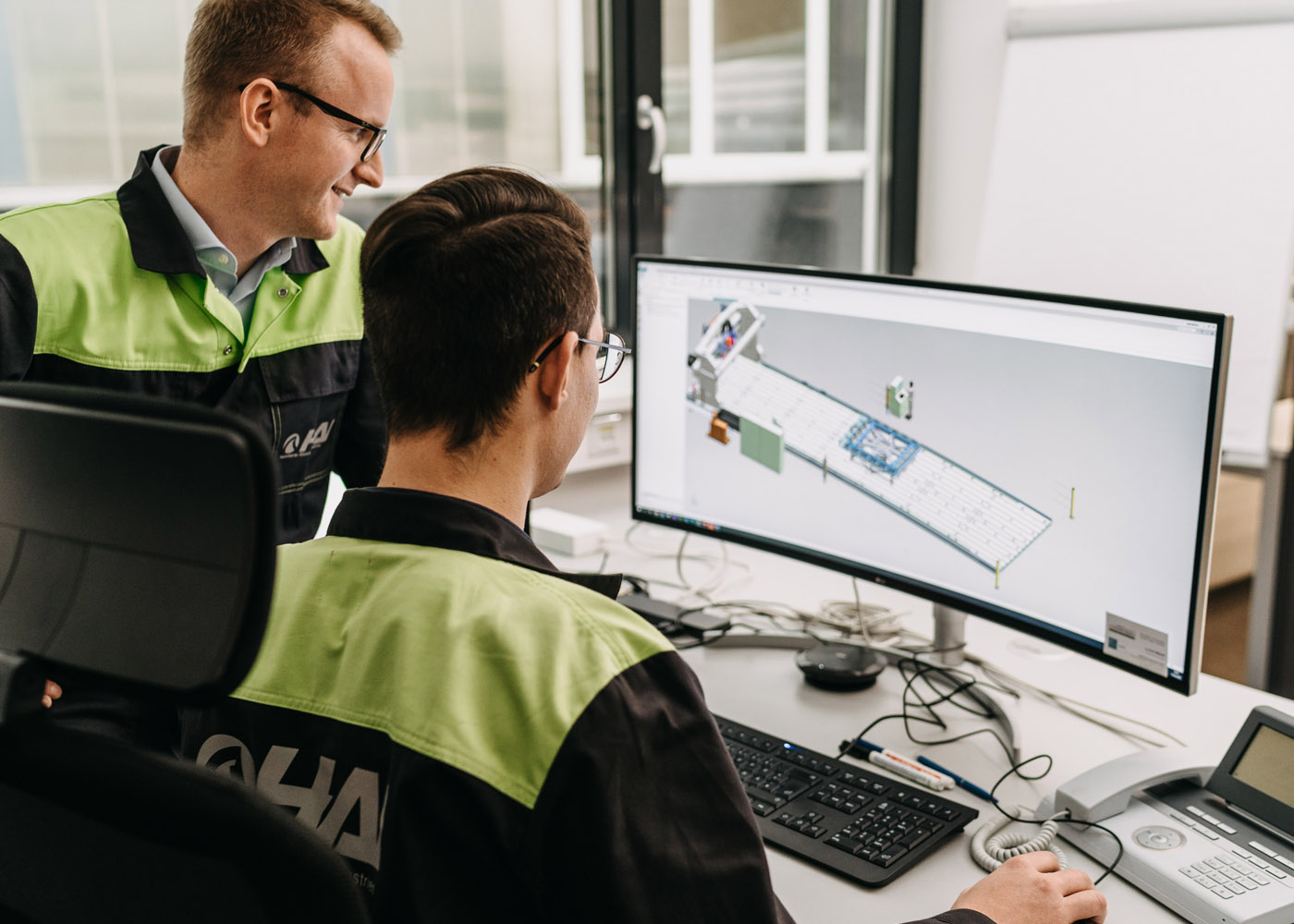

Our development and production of e-mobility products is facilitated by our high level of in-house casting, extrusion and processing expertise across our fully integrated sites as well as our in-house prototype construction facilities. The result is that we save valuable time and expense in the development process, and we shorten time-to-market for OEMs.

This reflects our position as a technological leader thanks to our comprehensive research and development know-how and numerous cooperative agreements in this field. Throughout the process we always focus on our customers’ requirements and wishes. As a reliable solutions partner with a long-term focus, we provide support to our customers until premium-quality, complex components are actually produced according to the respective specifications.

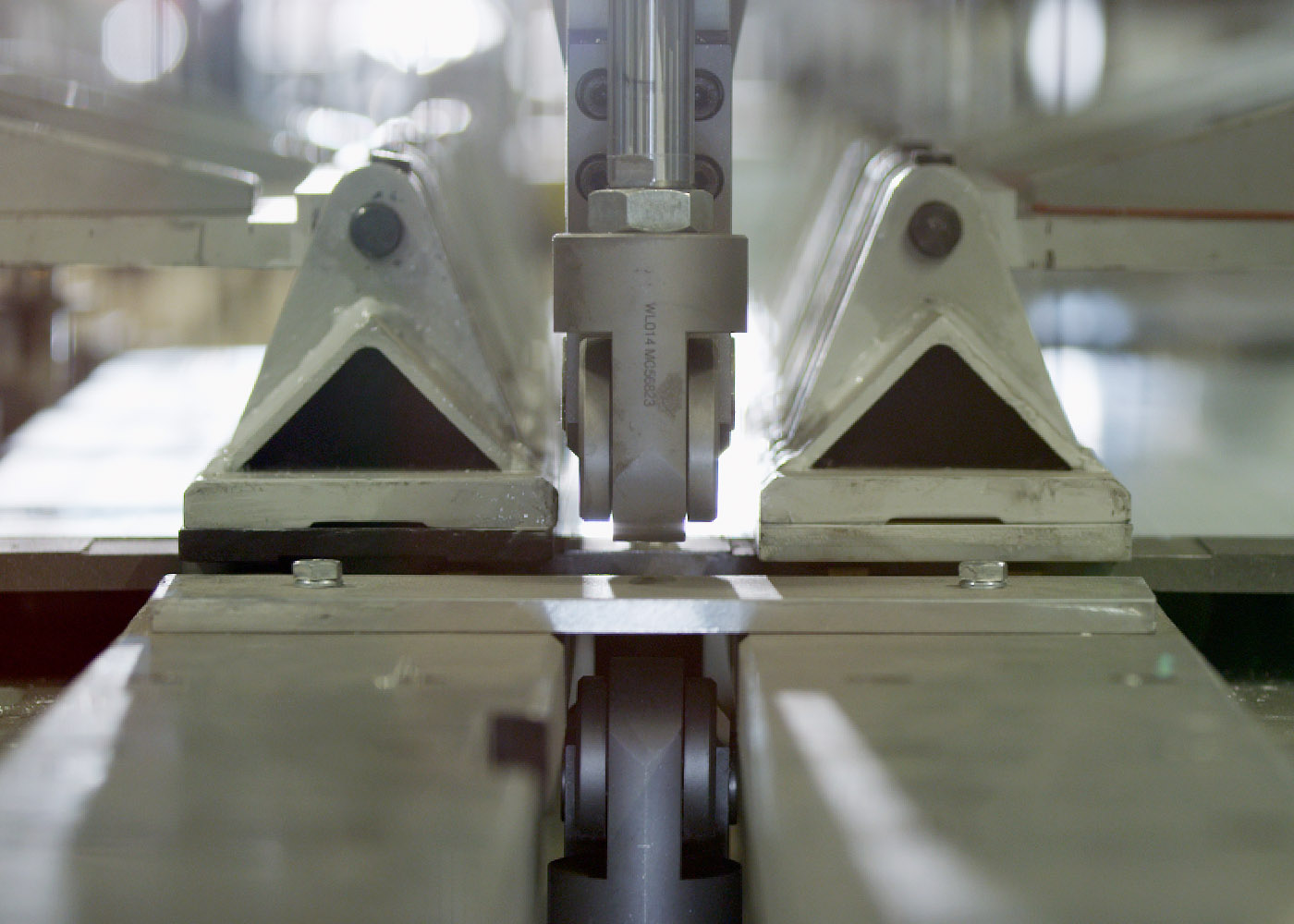

Innovative FSW welding procedure

Friction stir welding (FSW) enables us to produce battery trays in a highly efficient manner. Even sophisticated components that will subsequently have to bear considerable weight can be welded and processed securely and reliably thanks to the resulting weld thickness.

The components are milled and then assembled in our own machining centres. Thanks to the low heat input in the friction stir welding process, subsequent straightening and grinding can generally be eliminated.

Less is more: light-weight construction

The combination of alloy expertise, innovative production procedures and our experience of the sector makes HAI one of the few partners in Europe which is able to develop, produce and supply such complex components as battery housings with very specific requirements in terms of weight and stability.

Do you need HAI-end aluminium components for e-vehicles?

Dr.-Ing. J. M. Michael Heußen

Sales Director, Automotive & Transport Extrusion, HAI Group